News

Green energy and full digitisation mean savings for companies' budgets. Foundry Goes Green seminar

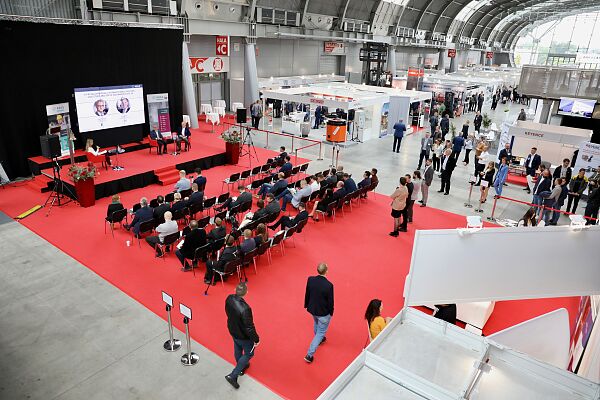

The Targi Kielce Industrial Autumn brought together entrepreneurs from the foundry industry. On Wednesday, many listened to the lectures organised as part of the Foundry Goes Green technical seminar.

The presentation of Anna Dębowska from Luneos Polska on how much can be saved as a result of the energy transformation and why it is a strategic necessity for enterprises today attracted the attention of a wide audience. - A company can take advantage of a wide range of opportunities as part of the energy transformation. The full implementation leads to a complete transition to green energy, which generates huge savings - she said. She offered the example of a company that installed the full Energy Transformation 360 package, including a heat pump, photovoltaics, cogeneration, LED lighting. Thus the company saved PLN 28 million in 15 years.

Digitisation contributes to time, energy and finance saving as well as improving all processes in the company.

-Advanced ERP management software allowed for full integration of all areas, i.e. production, sales, purchases, quality control - said Wojciech Kwilosz, production director at Odlewnie Polskie [Polish Foundries].

He explained, that thanks to the fact that the abas ERP system is installed in all production areas, data from the consecutive production stages is available online for a wide range of interested parties - planners, technologists, sales department. - Thanks to the Laboratory module, we have access not only to production data, but also to quality data related to each material and casting - explained the director.

- The abas system supports all processes in iron, cast steel, aluminum foundries. Each implementation adds new functionalities dedicated to a given company - described Łukasz Rasała, board member at abas Business Solutions Poland. - We have implemented two major innovations in Polish Foundries, the first in management and smelting, sub-products handling. The second is planning automatic pouring lines with appropriate stacking.

Abas makes it possible to handle the entire production process, ranging from the material entry into the warehouse through control, planning and core production, management and planning, pouring, cast removal, cleaning, and selling.

Director Kwilosz from the Polish Foundries emphasised that full digitisation facilitates workflow and allows for quick decisions, including financial ones. - abas collects absolutely all production, financial and accounting data, which allows you to quickly have information and decide what to do. Data can be processed in various ways, only our imagination limits us - emphasised director Kwilosz.

The AGH University of Science and Technology in Krakow join the autumn METAL trade fair to talk about Industry 4.0 Technology, which is one of the fields of study at this Krakow university. AGH graduates, having completed their studies, are ready to work in companies operating in the broadly defined fourth industrial revolution area. Professor, PhD. Hab Rafał Dańko, vice-rector of the university, prof. dr hab. Engineer Marcin Górny, the dean of the Faculty of Foundry AGH UST and dr hab. Engineer Paweł Malinowski, the leader of the 4.0 development program in the foundry department, also discussed the education of staff. They pointed out that it is not easy to encourage young people to choose these lones of study.

Christian Kurtsiefer, General Manager of KMA Umwelttechnik GmbH, spoke at the end of the seminar - why ecological foundries rely on energy-efficient filtration of exhaust air.