INDUSTRIAL SPRING 2024 (19-22.03.2024)

STOM-TOOL - BLECH & CUTTING - LASER - ROBOTICS - FIX, Welding, Expo-Surface, Fluid Power, Control-Stom, 3D Printing Days

IMPONAR Sp. z o.o.

- ul. Krasickiego 44, 97-500 Radomsko, Poland

- 44 6821444

- imponar@imponar.pl

- www.imponar.pl

Description

www.filtracjacieczyprzemyslowych.pl

We also supply industry with professional machinery, tools and equipment, especially useful in production and maintenance departments.

Electronic catalog http://narzedzia.imponar.pl

IMPONAR is an authorized distributor of products:

- Stahlwille

- Mahr

- FORMAT

- G25

- SANDVIK Coromant

- BAHCO

- BOSCH

- HEXO

Products

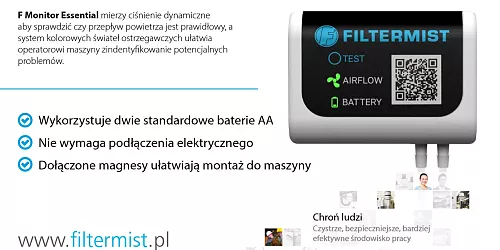

The F Monitor Essential measures velocity pressure to check the airflow through the Filtermist oil mist collector is correct. It uses two standard AA batteries, so no electrical connection is required, and it attaches to the machine using magnets.

The Bluetooth enabled F Monitor 2 measures airflow and time, and the F Monitor 2+ also monitors vibration and motor temperature - making it even easier to identify when your Filtermist unit needs servicing.

All F Monitors can be retro-fitted to the complete Filtermist range and are sold as an optional accessory on all Filtermist units.

Łatwa i intuicyjna obsługa urządzenia dzięki dużemu, w pełni dotykowemu wyświetlaczowi

Dzięki swoim kompaktowym rozmiarom, automat jest bardzo mobilny i można go łatwo przemieszczać w różne miejsca.

Elastyczność w konfiguracji przestrzeni wewnątrz automatu, co umożliwia dostosowanie go do różnych potrzeb.

System autoryzacji pozwala na kontrolę dostępu pracowników, zarówno indywidualnie, jak i grupowo, zwiększając bezpieczeństwo i kontrolę nad procesem wydawania towarów.

Sheet lenght up to mm 2500

Sheet thickness Alu mm 1,5

Sheet thickness galvanized steel (<400 N/mm²) mm 1,2

Sheet lenght inox (<600 N/mm²) mm 0,8

Max. feed (depending on cutting shape and material) m/min 30

Power connection 3 x 400 V/50 Hz x

Operating pressure bar 8

Net weight approx. kg 850

Low power consumption

Mechanical foam breaker

Compact design

Hygenised distillate

Recovery of process water

The evaporator operates fully automatically. The sensors monitor the process and prevent system overload. The system is cleaned almost fully automatically at fixed intervals. Generously sized doors ensure free access to the machine components. The distillate is hygenised by the high evaporation temperature of approx. 100°C and can be re-used in the production.

Simply go to the machining plant and clean it in next to no time: That’s how easy it is with the mobile MKR units for complete cleaning. They can be used to extract, care and then return contaminated metalworking fluid to the production process in only 15 minutes, including cleaning the metalworking fluid tank.

The high-performance MKR units type SF 500, SF 700 and SF 1000 combine several cleaning methods in one system: Liquid and swage suction apparatus, vacuum filter and high-pressure cleaner. The integrated swarf deals with solids and swage; liquids are cleaned by passing them through a vacuum filter.

The drained machine tank is cleaned using the high-pressure lance. The maintained liquid is returned to the cleaned machine by the return pump, while the tramp oils remain in the cleaning unit.