INDUSTRIAL SPRING 2024 (19-22.03.2024)

STOM-TOOL - BLECH & CUTTING - LASER - ROBOTICS - FIX, Welding, Expo-Surface, Fluid Power, Control-Stom, 3D Printing Days

IPG PHOTONICS Sp. z o.o.

- Wyczółkowskiego 8, 44-109 GLIWICE, Poland

- +48 32 721 22 20

- sales.poland@ipgphotonics.com

- www.ipgphotonics.com

Description

The company supplies its products globally to OEMs, system integrators and end customers across a broad spectrum of industries and markets.

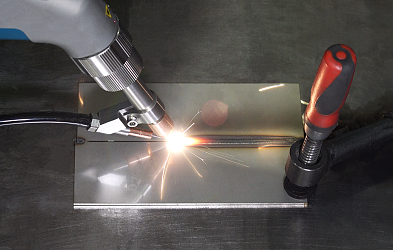

New to the company's product range are standard and turnkey systems for laser welding, drilling, cleaning and other material surface treatment processes.

IPG Photonics laser welding systems are equipped with the innovative LDD-700 system, which enables real-time measurement of the depth of penetration. LDD-700 allows obtaining information about the laser welding process and archiving this data for each welded part.

The LightWELD hand-held laser welding and cleaning system, which enables beginners and professional welders to produce high-quality welds, will also be demonstrated at this year's show.

IPG Photonics Sp. z o.o. has a well-stocked warehouse of spare parts in Poland, a network of professionally trained service and technical support engineers and a welding laboratory, which allows performing technological tests for customers.

Products

Mode of Operation: Continuous Wave/Modulated

Modulation Frequency, kHz: 0-5

Max. Average Power, W: 3500 / 7000 / 11000 / 18000

Power Tunability, %: 10-100

Power Stability*, %: <±2

Laser Illumination Area**, mm: 200 × 200

Power Density Uniformity, %: ±5

Cabinet Dimensions (W × D × H), mm: 430 × 808 × 567 / 430 × 808 ×700 / 430 × 808 × 902

Supply Voltage, VAC: 400-480 3-phase, 50/60 Hz

Weight, kg: 150 / 200 / 250

Cooling: Water

Energy Efficiency, % 52 Typical

- Single-mode Core up to 2 kW

- Ring Beam up to 5 kW

- Automatic Switching Between Different Optimal BPPs

- Easy Process Optimization and Automation

APPLICATIONS:

- Battery Manufacturing

- High Precision Single-mode Keyhole Welding

- High Speed Welding with No Spatter, Cracking and Porosity

- air-cooled 1500W continuous wave laser beam generator, ytterbium fiber laser system

- optical fiber with a length of 5 or 10 meters and a diameter of 50 μm

- adjustable power range from 10% to 100% of maximum output power

- Class 2M guiding laser pointer, with a peak power of 1mW

Portable laser welding head:

- optical configuration to provide a 150 μm spot on the workpiece

- Red laser pointer for correct positioning on the workpiece

- Wobble function: oscillation of the laser beam, oscillation width in the range of 0 - 5 mm, frequency in the range of 0 - 300 Hz

- welding gun with safety system with double trigger

- integrated contact safety sensor; beam emission is allowed only when the nozzle is in contact with the workpiece

- plasma sensor - additional protection against the possibility of direct beam emission over long distances

- integrated process gas feed - control of the gas flow from the base unit

2DHPS scanner for laser welding

LDD-700 system for real-time welding depth measurement