INDUSTRIAL SPRING 2024 (19-22.03.2024)

STOM-TOOL - BLECH & CUTTING - LASER - ROBOTICS - FIX, Welding, Expo-Surface, Fluid Power, Control-Stom, 3D Printing Days

METAL TEAM Sp. z o.o. Sp. k.

- Unii Lubelskiej 5, 35-016 RZESZÓW, Poland

- +48 34 326 12 15

- metalteam@metalteam.pl

- www.metalteam.pl

Description

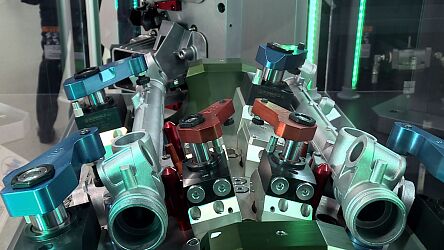

• MILLING MACHINES

• LATHES

• GRINDERS

• EDM (ELECTRICAL DISCHARGE MACHINING) MACHINES

• AUTOMATION.

The machinery offered by Metal Team include a broad range of numerically-controlled machines, such as: CNC machine tools, automatic lathes, CNC milling centres. Today our offer continuously comprises of top-class CITIZEN swiss type automatic lathes, MIYANO automatic lathes, BROTHER boring and tapping centres and OKAMOTO grinders, SMEC, Tongtai& Z-Mat milling centers. Moreover, Metal Team supplies a full range of supplementary equipment, such as barfeeders, chip conveyors or automation elements.

For as many as 15 years, Metal Team has participated in designing and developing automated solutions - engineering and producing hydraulic clamping systems and supplying comprehensive technological solutions for robotized production systems and manufacturing cells in compliance with customer expectations as well as applicable regulations.

The CNC machinery robotization and automation solutions offered by Metal Team allow our customers to meet the challenges of the ever-demanding and competitive market. We specialize in “turnkey" projects that include delivery and production start-up of cells with different sorts of CNC tools, supporting equipment (e.g. presses, stoves, marking machines, etc.), feeders, blowing, washing and measuring units, based on the work of industrial robots of various suppliers. Acting as an integrator, it is our priority to meet the customer expectations, at the same time being flexible in assembling cell equipment.

Based on our many years' experience, and in an effort to meet our clients' expectations, Metal Team developed the robotic pallet systems Rexio®. The systems are designed in accordance with the current technological trends, i.e. simplification of solutions, mobility, flexibility and ease of integration into existing work environment.

Download

-

Rexio-PL-2024.pdffile size: 2.37 MB

-

Tech-Team-PL-internet.pdffile size: 1.74 MB

Products

Kawasaki or Fanuc robot, 7 kg payload capacity and 0.9 m range with operating space limit

safety scanner

workpiece blow-off station

two grippers and blow-off nozzle

EC declaration of incorporation, operation and maintenance manual

remote deployment support

OPTIONAL EQUIPMENT

custom robot griping jaws

dipping station

workpiece re-grip station

3-colour signal light column

workpiece deburring station with flexibility adjustment

workpiece separator

Maximum machine door weight 150 kg

Door opening direction Left, right

Suitable for double doors Yes

3 pallets 990 x 600 mm, max. 40 kg/pallet

Kawasaki or Fanuc robot, 10 kg payload with operating space limiting

coolant drip pan (under pallets)

perimeter safety fencing, 2.5 m long, 2.3 m high – cat. 4 safety rating

pneumatic gripper and blow-off connection

REXIO® coating RAL 9003

main controller

EC declaration of incorporation, operation and maintenance manual

remote deployment support

OPTIONAL EQUIPMENT:

pallet 990 x 600 mm, max. 40 kg/pallet

pallet 990 x 600 mm, max. 120 kg/pallet

pallet workpiece separator for specific application

workpiece blow-off station

workpiece deburring station with flexibility adjustment

on-demand part inspection station

dipping station

vision system

workpiece re-grip station

3-colour signal tower lights

custom robot grippers

HMI control panel

Kawasaki or Fanuc robot with up to 35 kg payload

security scanner instead of a perimeter safety fencing

design, installation, set-up, CE certification

two conveyors to specification

robot with dedicated range and payload capacity

visual system with stand

HMI control panel

PC with display for visual system programming

pneumatic gripper and blow-off connection

safety scanner

main controller

EC declaration of incorporation, operation and maintenance manual

remote deployment support

OPTIONAL EQUIPMENT

custom robot grippers

workpiece blow-off station

workpiece re-grip station

dipping station

workpiece deburring station with flexibility adjustment

on-demand part inspection station

3-colour signal light column

two pallets

pallet docking system

robot with dedicated range and payload capacity

HMI control panel

pneumatic gripper and blow-off connection

fencing

main controller

EC declaration of incorporation, operation and maintenance manual

remote deployment support

OPTIONAL EQUIPMENT

custom robot grippers

workpiece blow-off station

dipping station

workpiece deburring station with flexibility adjustment

workpiece re-grip station

on-demand part inspection station

3-colour signal light column