INDUSTRIAL SPRING 2024 (19-22.03.2024)

STOM-TOOL - BLECH & CUTTING - LASER - ROBOTICS - FIX, Welding, Expo-Surface, Fluid Power, Control-Stom, 3D Printing Days

PIAB POLSKA Sp. z o.o.

- ul. Astronomów 1, 80-299 GDAŃSK, Poland

- 587850850

- biuro-pl@piab.com

- www.piab.com/pl-pl

Description

Our customers are in just every sector, including the Food & Beverage, Automotive, Packaging, Logistics & Warehousing, E-commerce, Electronics, Chemicals, and Pharmaceutical industries, and general manufacturing.

With sales of c. 1.9 BSEK, more than 900 employees and 4 divisions, Piab is a global organization, serving customers in more than 100 countries from a network of subsidiaries and distributors. Since 2018, Piab has been owned by Patricia Industries, part of Investor AB.

Evolving ourselves. Evolving you. Evolving automation.

Download

-

Sievingstation-MPS5-EN.pdffile size: 529.74 KB

-

Sievingstation-MPS30-EN.pdffile size: 665.73 KB

-

Sievingstation-MPSX1-EN.pdffile size: 773.01 KB

-

EN-Handout-Additive-Manufacturing-Piab-1.pdffile size: 2.37 MB

-

IB-MPS-pl-PL-PRINT.pdffile size: 1.06 MB

-

Rev02-pl-PL-Handout-Additive-Manufacturing-print-5.pdffile size: 2.17 MB

Products

• Screen area approx. 1200 mm2

• Mesh sizes of 63, 75, 90 and 100 μm

• Container volume:

• Receiver – 30 litres

• For correctly sized particles – up to 20 litres

• For oversize particles – 5 litres

• 7” HMI with clear menu navigation

• Recipe administration for powder management

• Operating voltage 110 – 230 V; 50 – 60 Hz

• Max. power consumption 0.5 W

• Air pressure 4 – 6 bar

• Screening capacity (3 litres)

• Titanium, nickel, stainless steel, approx. 30 seconds

• Aluminium approx. 60 seconds

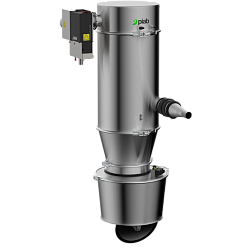

Our COAX® Technology, the most energy efficient way to produce vacuum, is used in the pump.

Material in contact with the conveyed product is in compliance with FDA.

Conveyor is CE approved/

Steel quality ASTM 316L (stainless steel, acid resistant), mechanically polished.

Designed according to USDA guidelines.

Automatic filter cleaning.

Hygienic design making maintenance and cleaning simple.

Smooth installation and easy to use.

High throughput with a small footprint.

0.5 liters per conveying cycle.

Material: PA, PTFE, SS, AL, ASTM316L, EPDM, NBR

Noise level: 69 - 73 dBA

Temperature: 0 - 60 °C

Weight: 13 kg

Air consumption (Max): 8,7 Nl/s

Air consumption, range: 6,6-8,7 Nl/s

Feed pressure (Max): 0.7 MPa

Feed pressure (Range): 0.4 - 0.6 MPa

Vacuum: 41 - 56 -kPa

Our COAX® Technology, the most energy efficient way to produce vacuum, is used in the pump.

Material in contact with the conveyed product is in compliance with FDA, EC No. 1935/2004 and EC No. 10/2011.

ATEX Dust certified.

Steel quality ASTM 304 (stainless steel), pickled surface treatment.

Antistatic filter and seals.

Automatic filter cleaning.

Smooth installation and easy to use.

High throughput with a small footprint.

Our COAX® Technology, the most energy efficient way to produce vacuum, is used in the pump.

ATEX Dust certified.

Steel quality ASTM 304 (stainless steel), pickled surface treatment.

Antistatic filter and seals.

Automatic filter cleaning.

Smooth installation and easy to use.

High throughput with a small footprint.

Our COAX® Technology, the most energy efficient way to produce vacuum, is used in the pump.

Material in contact with the conveyed product is in compliance with FDA, EC No. 1935/2004 and EC No. 10/2011.

ATEX Dust and Gas certified.

Steel quality ASTM 316L (stainless steel, acid resistant), mechanically polished.

Designed according to USDA guidelines.

Antistatic filter and seals are available.

Automatic filter cleaning.

Hygenic design making maintenance and cleaning simple.

Smooth installation and easy to use.

High throughput with a small footprint.

Wide capacity range from 2 to 56 liters per conveying cycle (up to 15 tons per hour).