HEAT TREATMENT (24-25.09.2024)

4. Metals Heat Treatment Expo

CAST METAL

- ul. Królewiecka 15/5, 54-110 WROCŁAW, Poland

- 71 358 44 54

- biuro@castmetal.pl

- www.castmetal.pl

Description

Products

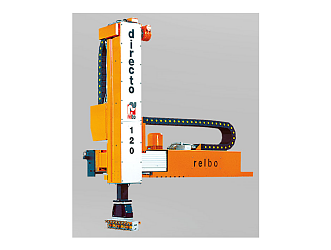

With an empty speed in the order of 230 cycles/hour, the Transal is the first step towards the automation

of die casting machines, to which it gives a rapid and constant pace, to the benefit of productivity and quality of the castings. The movements of the ladle, obtained by means of brushless motors and frequency variators, are adjustable in speed, acceleration and deceleration. The TRANSAL EVO is able to move the two axes simultaneously, speeding up the transport of the alloy from the furnace to the shot sleeve for pouring.

The absence of mechanical limit switches makes the machine completely manageable and configurable from the HMI.

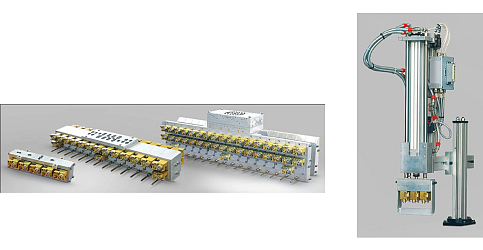

Easy-to-install system

Compatible with any vent or mechanical valve

Easy to use and maintain

Available for Zamak applications

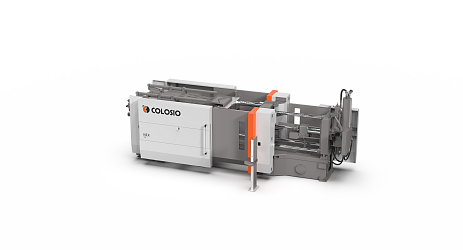

1.RENEWED INJECTION UNIT

Injection group with regenerative system, extreme precision in injection phase control, servo-valves for real-time control of speed and pressure, digital injection lift.

2. INCREASED SAFETY AND SIMPLIFIED MAINTENANCE

Closing group protections ensured by high-precision photocells and accessibility to maintenance areas freefrom obstructions. Increased safety

and simplified maintenance.

3. REDUCED FOOTPRINT AND IMPROVED ERGONOMICS

Analysis and study of components and materials have allowed the development of a more compact machine with improved ergonomics

for the operator.

4. GREEN AND SUSTAINABLE

The integration with the GREENLINE system is comprehensive, resulting in minimal power consumption and a significant reduction in the water required for cooling.

5. STATE-OF-THE-ART CONTROL SYSTEM

State-of-the-art, intuitive HMI

(Human-Machine Interface) featuring a 24” touchscreen and programmable rotating command for machine motion management.