INDUSTRIAL SPRING (25-28.03.2025)

STOM-TOOL - BLECH & CUTTING - LASER - ROBOTICS - FIX, Welding, Expo-Surface, Fluid Power, Control-Stom, 3D Printing Days

Guangdong Ur Welder Co. Ltd.

- 14th Floor, Build.A1, West Lake Zhigu Ind. Z, Huicheng Distr, PRC-516005 HUIZHOU City, Guangdong Prov., China

- 18825914749

- SALES2@URWELDER.COM

- www.urwelder.com

Description

Ur Welder 's creative team has more than ten years of experience in resistance welding industry, and now we have formed a strong R&D team with professors and doctors as the core. Ur Welder insists on investing a large amount of R&D funds every year to maintain the competitiveness of its products and to ensure the leading technical R&D strength.

Since its establishment, Ur Welder has been committed to serving the high-tech manufacturing industry, providing advanced metal welding products and solutions for global high-end customers in the fields of automobile body,automobile parts, automobile electronics, motor stand-alone, new energy batteries, solar photovoltaic, electric light source, enameled wires, coils, wiring harnesses, capacitors, protectors, sensors, relays, optical communications, and pin vibration industry, etc. Ur Welder is a leading supplier of advanced metal welding products and solutions for the global high-end customers.

After more than ten years of development, Ur Welder has completed the layout of multiple industrial bases, not only in the domestic market in the forefront, in Europe and Asia has also established a good business channels and technical cooperation, the products have been sold to more than ten countries and regions, recognized by many well-known domestic and foreign enterprises and customers.

Download

-

ZIPUR-WELDER-HUANDZK-Product-Catalog-241104.pdffile size: 899.51 KB

Products

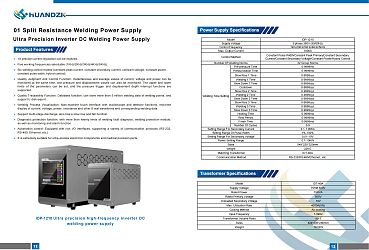

Five working frequencies selectable (1KHz/2KHz/3KHz/4KHz/5KHz).

Six welding control modes (constant peak current, constant secondary current, constant voltage, constant power, constant pulse width, hybrid control).

Quality Judgment And Control Function: Instantaneous and average values of current, voltage and power can be monitored at the same time, and pressure and displacement values can also be monitored. The upper and lower limits of the parameters can be set, and the pressure trigger and displacement depth interrupt functions are supported.

Quality Traceability Function: Database function, can store more than 5 million welding data of welding points, and support U disk export.

Welding Process Visualization: Man-machine touch interface with oscilloscope and detector functions, real-time display of current, voltage, power, resistance and other 8 real waveforms and corresponding welding data.

Support multi-stage discharge, also has a slow rise and fall function.

Diagnostic protection function: with more than twenty kinds of welding fault diagnosis, welding protection module, as well as monitoring and alarm function.

Automation contro